Wellbore Cleanout

A TRUE reverse displacement system.

Wellbore Cleanout

A TRUE reverse displacement system.

A TRUE reverse displacement system.

Current wellbore cleanout technology has evolved overtime to include multiple mechanical devices to remove debris. Inability to reverse circulate the wellbore while rotating and reciprocating during cleanout created the need for additional equipment. Complicated filtration devices, boot baskets, circulating subs, magnets, and other accessory equipment have a finite capacity to carry debris to the surface and unduly complicate the process.

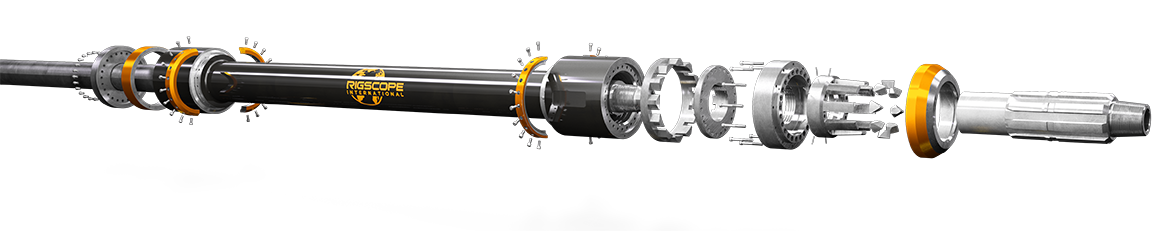

DeltaScope® WBC revolutionizes wellbore cleanout. By incorporating the industry-best practice of rotating and reciprocating while reverse circulating, leveraging gravity and higher fluid velocity inside the workstring allows for the removal of infinite volumes of debris. Solids either end up in the rat hole or on the surface – not strung out in the wellbore. Simplifying this process eliminates the need for superfluous equipment, reducing potential downhole failure points and increasing efficiency.

PROCESS IMPROVEMENTS:

- True reverse circulating displacement

- Reduction of tools needed for cleanout (boot baskets, magnets, etc.)

- Full rotation and reciprocation throughout the process

- Proprietary design allows for independent displacement of the riser and well bore

The patented DeltaScope® Annular Protection Tool (APT) is precision-engineered to facilitate the management of a variety of downhole operations with unprecendented accuracy. DeltaScope’s proprietary pressure control at the wellhead protects the annular blowout preventer eliminating costly damage and reducing downtime without compromising subsurface functionality. Safety, precision and reliability – at full working pressure. That’s the DeltaScope® difference.