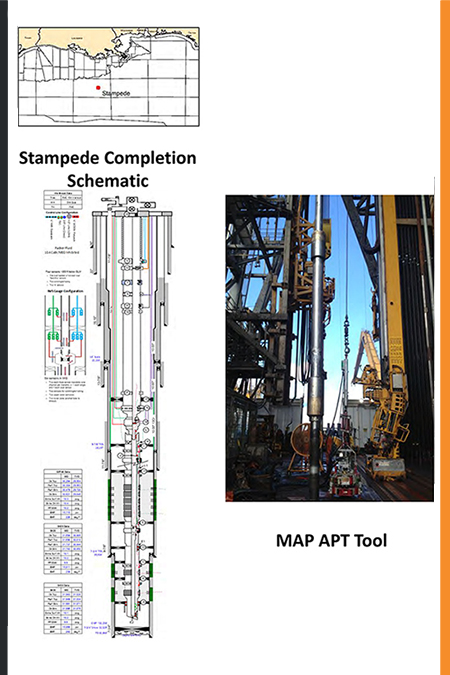

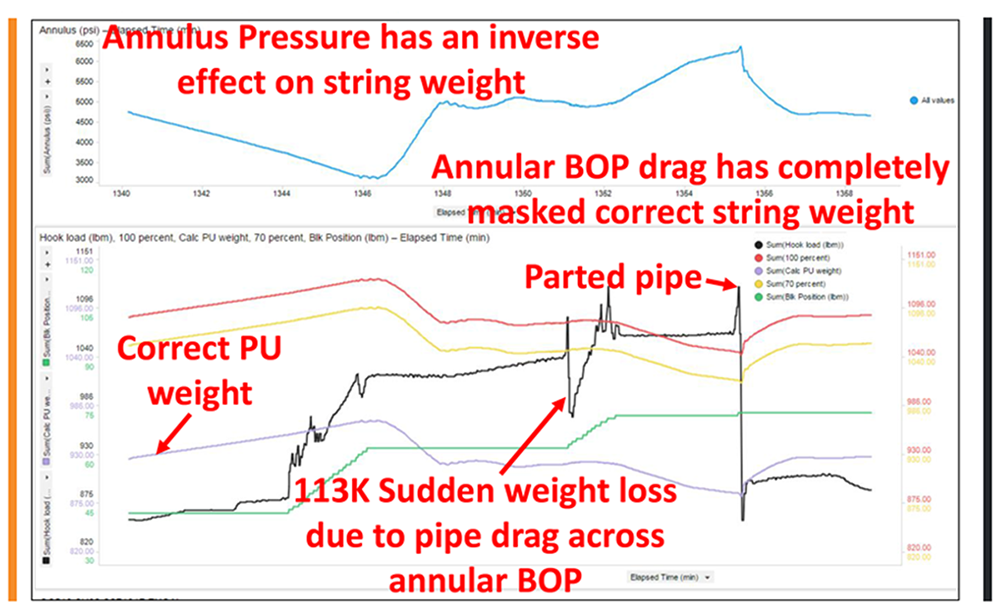

The complex nature of the Gulf of Mexico Stampede completion design called for improved precision tools to maintain operational efficiencies during installation. Some early challenges related to annular stripping and downhole tool manipulation during single-trip multi-zone frac ack operations resulted in reduced efficiency in tool positioning and manipulation, as well as a difficult fishing operation due to a parted service tool.

To prevent recurrence and overcome these challenges, the team deployed a telescoping annular protection tool (APT) that effectively eliminates/minimizes annular drag between the traditional annular and workstring interface.

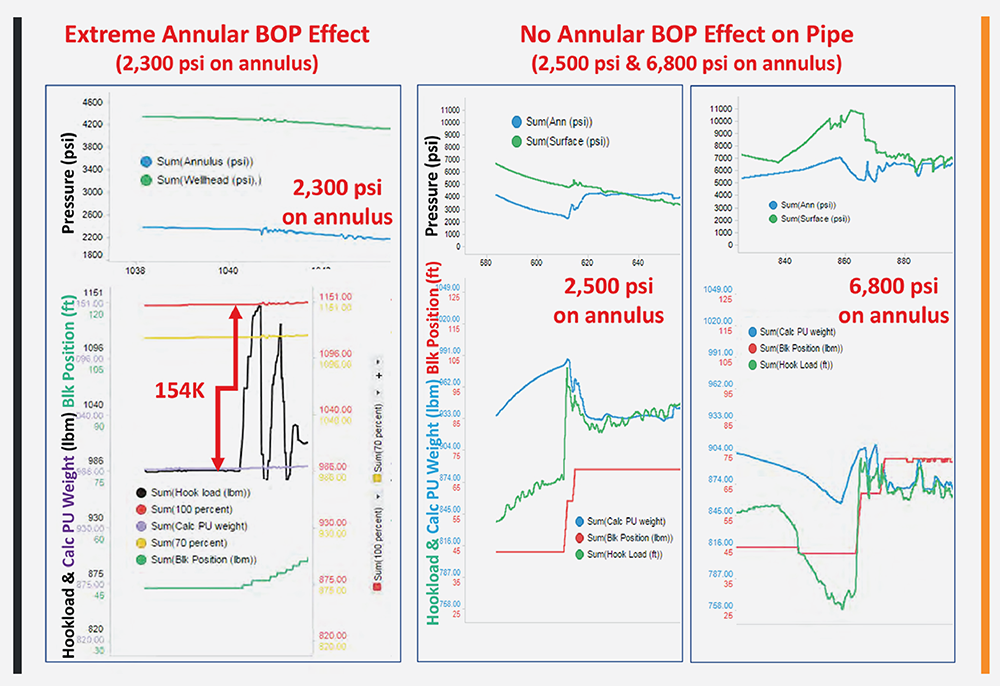

There is simply no annular drag on the pipe when using the APT. Drag is effectively zero while moving pipe.

The complex nature of the Gulf of Mexico Stampede completion design called for improved precision tools to maintain operational efficiencies during installation. Some early challenges related to annular stripping and downhole tool manipulation during single-trip multi-zone frac ack operations resulted in reduced efficiency in tool positioning and manipulation, as well as a difficult fishing operation due to a parted service tool.

To prevent recurrence and overcome these challenges, the team deployed a telescoping annular protection tool (APT) that effectively eliminates/minimizes annular drag between the traditional annular and workstring interface.

There is simply no annular drag on the pipe when using the APT. Drag is effectively zero while moving pipe.

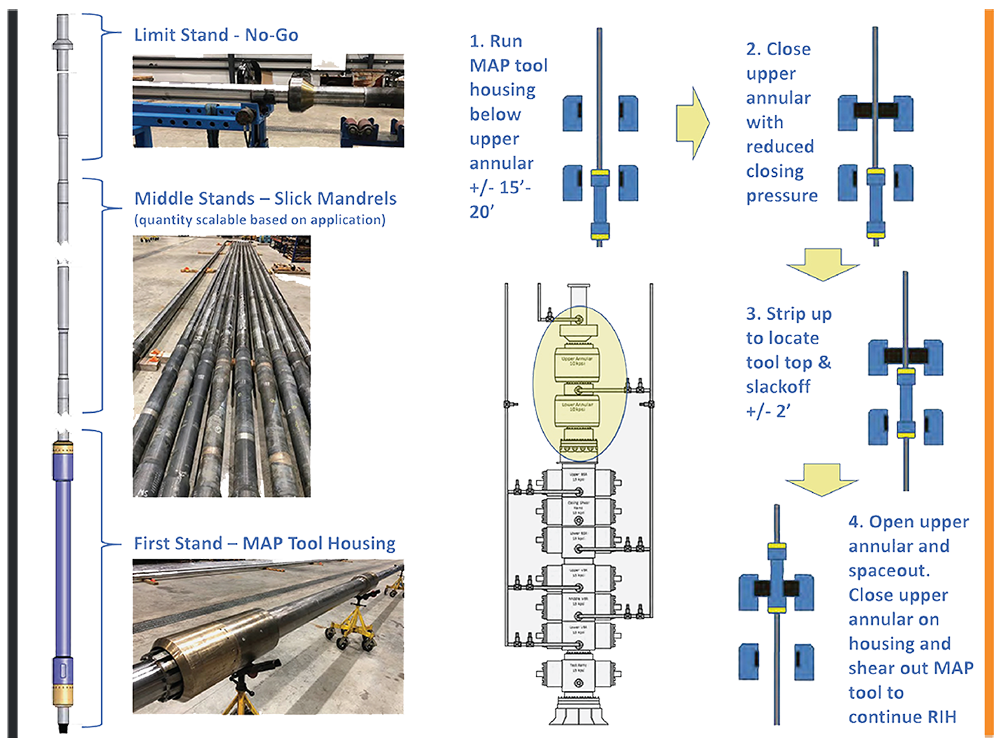

Annular BOP stripping can have significant & inconsistent drag due to:

- Surface area ~400 sq-in (7” OD pipe)

- Hydraulic loading

- Actual annular condition unknown

APT tool stripping uses a fit for purpose, engineered interface for minimal and predictable drag:

- Surface area ~44 sq-in (7” OD pipe)

- Not hydraulically loaded

- Not sensitive to annular condition

String weight is affected by pressure, requiring the maximum allowable string weight/overpull to be continuously evaluated real-time.

String weight is affected by pressure, requiring the maximum allowable string weight/overpull to be continuously evaluated real-time.

Using the MAP APT tool, we can continuously calculate string weights against actual values and safely move pipe across the annular BOP under pressure.

Using the MAP APT tool, we can continuously calculate string weights against actual values and safely move pipe across the annular BOP under pressure.

Efficiency improvements during frac pack operations

- Spotting frac treatments under pressure

- Pick up to reverse position with 7,000 psi on annulus

- Ability to strip to bottom (~256’) and close MSV sleeve with ~600 psi on annulus

Predictable pick-up weights

- Tension can be successfully transferred downhole through the MAP tool below the annular BOP (confirmed post-job analysis)

- Pick-up weights track calculated values

- ALWAYS know limits

Not sensitive to annular element condition

- No additional wear on annular element

- Facilitate rotation and reciprocation through the BOP under full working pressure

Efficiency improvements during frac pack operations

- Spotting frac treatments under pressure

- Pick up to reverse position with 7,000 psi on annulus

- Ability to strip to bottom (~256’) and close MSV sleeve with ~600 psi on annulus

Predictable pick-up weights

- Tension can be successfully transferred downhole through the MAP tool below the annular BOP (confirmed post-job analysis)

- Pick-up weights track calculated values

- ALWAYS know limits

Not sensitive to annular element condition

- No additional wear on annular element

- Facilitate rotation and reciprocation through the BOP under full working pressure